Accuracy and efficiency are paramount in the industrial production sector, which moves quickly. Welding, a cornerstone of many industries, demands accuracy and reliability to ensure quality products. This is where advanced weld controllers come into play. At Proteus Industry, we specialize in providing state-of-the-art weld controllers designed to meet the rigorous demands of modern manufacturing. With our WeldSaver 6 Legacy Series, industries can achieve unmatched precision and productivity in their welding operations.

What is a Weld Controller?

A weld controller is an essential device used in welding processes to regulate and monitor various parameters, ensuring consistent and high-quality welds. It manages critical aspects such as current, voltage, time, and cooling, enabling manufacturers to achieve precise results. By automating and optimizing the welding process, weld controllers minimize errors, reduce waste, and improve overall efficiency.

The Importance of Weld Controllers in Modern Industries

In industries where welding plays a vital role, the importance of a reliable weld controller cannot be overstated. From automotive manufacturing to aerospace engineering, weld controllers are indispensable for the following reasons:

- Enhanced Precision: They ensure consistent weld quality by controlling parameters with high accuracy.

- Increased Efficiency: Automated controls streamline the welding process, reducing downtime and labor costs.

- Improved Safety: Advanced features like real-time monitoring and fault detection prevent accidents and equipment damage.

- Energy Savings: Optimized welding processes result in reduced energy consumption, contributing to sustainability.

Key Features of Advanced Weld Controllers

Modern weld controllers, such as the WeldSaver 6 Legacy Series from Proteus Industry, offer cutting-edge features that set them apart from conventional devices:

- Real-Time Monitoring: Advanced sensors provide instant feedback on welding parameters, ensuring optimal performance.

- Automated Cooling Management: Efficient cooling systems prevent overheating and extend equipment lifespan.

- User-Friendly Interface: Thanks to intuitive controls and displays, operators can easily change settings and monitor procedures.

- Customizable Settings: Tailor the welding parameters to suit specific applications and materials.

- Robust Build: Designed to withstand harsh industrial environments, these controllers ensure durability and reliability.

Applications of Weld Controllers in Different Industries

Weld controllers are used across various industries to enhance welding processes. Here’s how they contribute to some key sectors:

- Automotive Industry:

- Essential for spot and seam welding in vehicle assembly lines.

- Ensures uniform welds for structural integrity and safety.

- Aerospace Industry:

- Supports precise welding of lightweight materials like aluminum and titanium.

- guarantees that stringent safety and quality requirements are followed.

- Electronics Manufacturing:

- Used for micro-welding in the production of circuit boards and delicate components.

- Guarantees precision in handling small-scale welds.

- Construction Industry:

- Facilitates welding of steel and other metals for structural frameworks.

- Enhances durability and longevity of constructions.

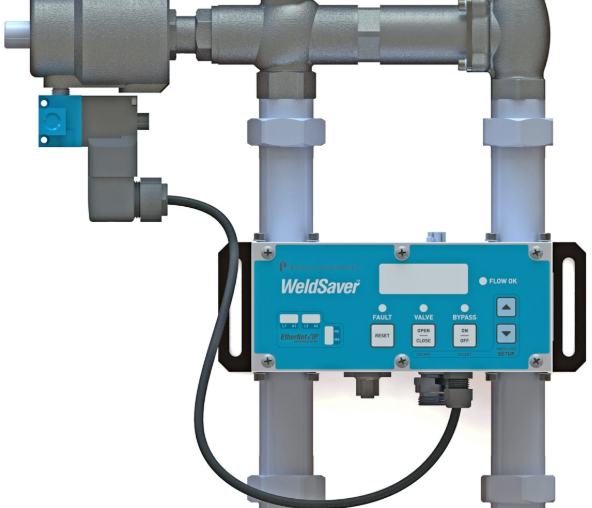

Introducing the WeldSaver 6 Legacy Series

The WeldSaver 6 Legacy Series from Proteus Industry demonstrates our dedication to quality and innovation in welding technology.

Designed for demanding industrial applications, this weld controller offers unparalleled performance and reliability. Key highlights include:

- High-Accuracy Monitoring: Real-time feedback ensures precise control over welding parameters.

- Integrated Cooling Management: Protects equipment by maintaining optimal operating temperatures.

- Compact and Durable Design: Fits seamlessly into existing systems and withstands challenging conditions.

- Energy Efficiency: Optimized processes reduce energy usage and operational costs.

To learn more about the WeldSaver 6 Legacy Series, visit our website at Proteus Industry.

Benefits of Choosing Proteus Industry for Weld Controllers

At Proteus Industry, we understand the unique challenges faced by manufacturers and engineers. That’s why our weld controllers are designed with your needs in mind. Here’s why you should choose us:

- Expertise and Experience: With decades of experience, we are leaders in welding technology.

- Quality Assurance: We put our products through a rigorous testing process to guarantee their performance and dependability.

- Customer Support: We offer dedicated support to help you get the most out of your investment.

- Innovative Solutions: Our continuous research and development keep us at the forefront of industry advancements.

Tips for Selecting the Right Weld Controller

Choosing the right weld controller is crucial for achieving the desired results. Consider the following factors:

- Application Requirements: Determine the precise needs of your welding process, such as material type and thickness.

- Controller Features: Look for advanced features like real-time monitoring, automated cooling, and customizable settings.

- Compatibility: Ensure the controller integrates seamlessly with your existing equipment.

- Supplier Reputation: Choose a trusted provider like Proteus Industry to guarantee quality and support.

The Future of Welding Technology

As industries continue to evolve, so does welding technology. Future advancements in weld controllers will likely focus on greater automation, AI integration, and enhanced energy efficiency. By staying ahead of these trends, Proteus Industry ensures our clients have the tools they need to remain competitive.

Conclusion

Advanced weld controllers are transforming how industries approach welding, offering precision, efficiency, and reliability. At Proteus Industry, we’re proud to provide cutting-edge solutions like the WeldSaver 6 Legacy Series to help our clients excel in their fields. Whether you’re in automotive manufacturing, aerospace, or construction, our weld controllers can elevate your operations to new heights.

Explore the possibilities with Proteus Industry’s weld controllers and take the first step toward optimizing your welding processes. For more information, visit us at Proteus Industry.