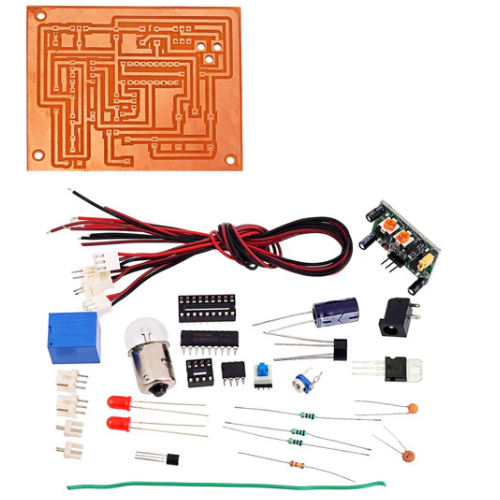

Thanks to hands-on engagement, learning about mechanical systems via do-it-yourself instructional kits and robotics projects develops practical knowledge. The operation of their underlying systems determines much of the assembled model’s performance and usefulness. Essential parts of mechanical systems allowing power and motion transfer are gears. Because of their purported improved performance benefits, helical gears are becoming more and more common among specific gear designs. Choosing gear systems that satisfy project needs and maximize energy efficiency presents the main difficulty for both students and enthusiasts. This article aims to find whether small-scale robotic systems and educational settings gain much mechanical efficiency from these gears.

Mechanical efficiency and its relevance in small systems

The mechanical efficiency of a system exposes the success rate of transforming input energy into useful motion. Helical gears improve control capabilities and reduce energy loss while giving smoother torque, therefore enabling DIY robotics systems to provide quiet and dependable performance from motor-driven systems.

Effective gear systems protect their components from early degradation and preserve performance levels as stated throughout the design phase. Students who want to understand fundamental engineering ideas and build robust models have to choose appropriate gear kinds.

The real benefits of using refined gear systems in learning

Within instructional settings, gears have two uses. Through dual-purpose gears that stay functional during the instructional process, students learn about power transmission, rotational motion, and torque management. When mechanical functioning calls for precise demonstrations, helical gears offer improved performance advantages. The noise-free operation of the system lets pupils concentrate on learning results by eliminating distractions from sound and malfunctioning mechanical elements.

Through gear train tests, investigating angled gear teeth mechanics helps students grasp sophisticated mechanical concepts. Angled gear teeth expose mechanical ideas spanning axial thrust together with torque load balancing and gear stress distribution. Since helical gears show more intricate mechanics than conventional gears, they function as smaller-scale engineering models that enable students to solve difficult engineering problems.

Motion accuracy is critical in robots. When sensor-driven vehicles and manipulator arms operate smoothly and stably, the system runs better. Because they keep constant contact during loading conditions, helical gears retain improved mechanical efficiency by delivering energy transfer with more fluidity. The feature helps systems where motion instability poses a threat to damaging both practical performance and educational results.

Exploring the long-term impact of efficiency on project success

Efficiency goes beyond instantaneous performance. The operation of robotics kits and instructional tools affects their maintenance needs and power consumption as well as their wear resistance. Parts of mechanical systems that run effectively experience reduced wear and tear. Reduced maintenance requirements resulting from longer-lasting equipment operation let students spend more time on design improvement by means of repeated tests.

When students and enthusiasts use kits with effective gear systems, their models eventually bring more delight. Mobile robotic design depends on efficient energy usage since it lets machines run more effectively with fewer energy losses. Basic system functionality running within predicted ranges offers necessary support for automated sensor system calibration and scientific hypothesis testing.

The success rates of integrated systems in advanced learning environments depend on gear performance since exact alignment between mechanical motion and coding interfaces is needed. The reaction of a physical system to digital inputs depends on gear systems that reduce backlash and maximize energy retention to reach the best efficiency. System synchronization will enable engineers to advance mechatronics knowledge and build intelligent machines.

How specific gear design choices shape learning experiences

Every gear design shows different qualities, but with certain gear types, the educational alignment becomes very obvious. Small robot projects and do-it-yourself kits give pupils chances to investigate helical gears in a classroom. These gears are perfect for both realistic simulations and classroom scenarios since they run silently and smoothly under different weights.

Using helical gears lets teachers and students study force distribution and efficiency curves without having to pay for expensive lab equipment. These gears stop reverse motion in particular configurations, thereby preserving experimental integrity. The function improves safety and utility all through the student-driven design process.

Helical gearbox systems seen in today’s instructional packages let students investigate challenging mechanical engineering ideas outside of conventional classroom guidelines. These characteristics let regular models become high-performance instruments for industrial process simulation. Learning mechanical engineering becomes easier when torque transfer increases and energy loss reduction allows more people to fully pursue STEM professions.

Conclusion: Unlocking efficient design through better components

Hence, to sum-up, successful engineering projects depend mostly on mechanical efficiency, which becomes essential while designing robotics systems and instructional kits. The development of learners’ knowledge and application of mechanical concepts depends critically on the correct utilization of components. Results of the analysis revealed the need for selecting the appropriate gears throughout this operation. Effective use of sophisticated gear systems reduces friction performance and enhances mechanical lifetime as well as operation accuracy. These characteristics improve the practical relevance as well as the instructional value. Consider online stores like KitsGuru, which provides dependable help along with well-selected components that enable people to improve their practical projects by means of better design and performance.