In the dynamic landscape of modern manufacturing, the humble paper cup has undergone a remarkable transformation. Once a simple vessel for beverages, it has become a symbol of sustainability and convenience, driven by technological advancements in cup making machines. Leading thermoforming technology company Shanghai Zhanshi Mechanical Equipment Co., Ltd. is at the front of this development. Their state-of-the-art cup making machines are not only enhancing production efficiency but also aligning with global sustainability goals.

An excellent illustration of Shanghai Zhanshi’s commitment to innovation is their most recent offering, the ZS-1220 PLC Control High Speed Thermoforming Machine. This cutting-edge equipment offers enhanced versatility and reliability, addressing diverse production needs with its advanced servo motor and cylinder driving systems

Moreover, the shift towards sustainable practices has led to the development of biodegradable and compostable paper cups. Cup making machines are now designed to accommodate these materials, reducing environmental impact and catering to eco-conscious consumers. The integration of smart sensors and AI in these machines further optimizes production processes, enabling real-time monitoring and predictive maintenance

Made-in-China.com

A Quiet Revolution in Paper Cup Manufacturing

Paper cups might seem ordinary, but behind every disposable cup is a sophisticated machine making it all happen with lightning speed and pinpoint precision. Welcome to the world of Cup Making Machines, where sustainability, engineering genius, and automation come together to transform the packaging sector. Shanghai Zhanshi Mechanical Equipment Co., Ltd. is at the forefront of the global trend toward innovative solutions as environmental restrictions tighten and consumer preferences change.

What Is a Cup Making Machine?

Definition and Functionality

A Cup Making Machine is a highly specialized type of machinery designed to manufacture paper or plastic cups efficiently and consistently. These machines automate the entire process, from feeding raw materials to shaping, forming, sealing, and even stacking the final products.

Types of Cups It Produces

- Cold drink cups

- Hot beverage cups

- Ice cream cups

- Yogurt and dessert containers

- Ripple-walled or double-walled cups

Why the Cup Making Machine Is a Manufacturing Game-Changer

– Speed and Volume

One of the biggest advantages is speed. A modern cup making machine, like those from Shanghai Zhanshi, can produce thousands of cups per hour. This level of automation allows manufacturers to meet rising market demand without compromising on quality.

– Cost Efficiency

Although buying a cup making machine might seem like a big investment at first, the labor and material cost benefits over time soon offset it. These devices provide reliable output, cut down on waste, and minimize human error.

– Precision Engineering

Cups must meet specific dimensions and strength requirements. These machines guarantee uniformity, which is critical for branding, stacking, sealing, and consumer experience.

Market Factors Contributing to the Growth of Cup Making Machines

– Rise in Food Delivery and Takeaway Culture

The surge in on-the-go lifestyles and the proliferation of food delivery services have caused a sharp increase in demand for disposable cups. Restaurants, coffee shops, and vending businesses rely on quick-turnaround, high-volume cup production.

– Environmental Legislation and Sustainability Push

Governments are increasingly pushing for alternative plastic, driving demand for paper-based packaging. Manufacturers need to switch to eco-friendly options fast, and that’s where cup making machines that handle recyclable or biodegradable materials become crucial.

Shanghai Zhanshi Mechanical Equipment Co., Ltd.: Pioneering Precision

– Who They Are

Shanghai Zhanshi has become a recognized leader in the development of high-speed, highly efficient thermoforming and cup making machinery. Known for reliability, innovation, and exceptional after-sales service, the company continues to elevate the global standard.

– Flagship Machines

Their ZS-1220 PLC Control High-Speed Thermoforming Machine and ZS-A12 Fully Automatic Paper Cup Machine are examples of how they integrate servo control, precise temperature regulation, and real-time diagnostics.

– R&D Focus

With ongoing investments in research and development, Shanghai Zhanshi remains agile—adapting their machines to changing materials, faster production cycles, and smart factory integration.

Features That Set Zhanshi Cup Making Machines Apart

1. High-Speed Output

Their machines have a high throughput for production on a commercial scale, producing 90 to 130 cups per minute.

2. Intelligent Control System

Equipped with PLC and touch screen interfaces, their systems are user-friendly and reduce the chance of errors.

3. Material Versatility

Zhanshi machines can easily adapt to many types of paper, including PE-coated paper, PLA-based biodegradable paper, and customized eco-materials.

4. Compact, Space-Saving Design

Despite their performance, these machines have a relatively small footprint, making them suitable for factories with limited space.

Applications Across Industries

– Food & Beverage

Fast-food chains, coffee shops, and vending services all rely on paper cups—and therefore on the machinery behind them.

– Healthcare

Sterile, disposable paper cups are also crucial in clinics and hospitals, where hygiene is non-negotiable.

– Events & Hospitality

Concerts, festivals, sports events, and hotels require vast quantities of disposable cups, usually printed with branding—something automated machines can handle flawlessly.

The Sustainability Edge

- PLA and Biodegradable Cups

Modern cup making machines now support PLA-coated and fully compostable papers. This ensures manufacturers can meet eco-regulations while maintaining product integrity. - Waste Reduction

Precision cutting and intelligent material usage reduce production waste—another cost-saving and eco-friendly benefit.

Transitioning to Automation: What Businesses Should Know

- ROI Timeline

With average machines paying for themselves in under 18 months, many companies see immediate operational benefits. - Workforce Optimization

Operators can manage multiple machines at once, freeing up staff for other critical areas of the business.

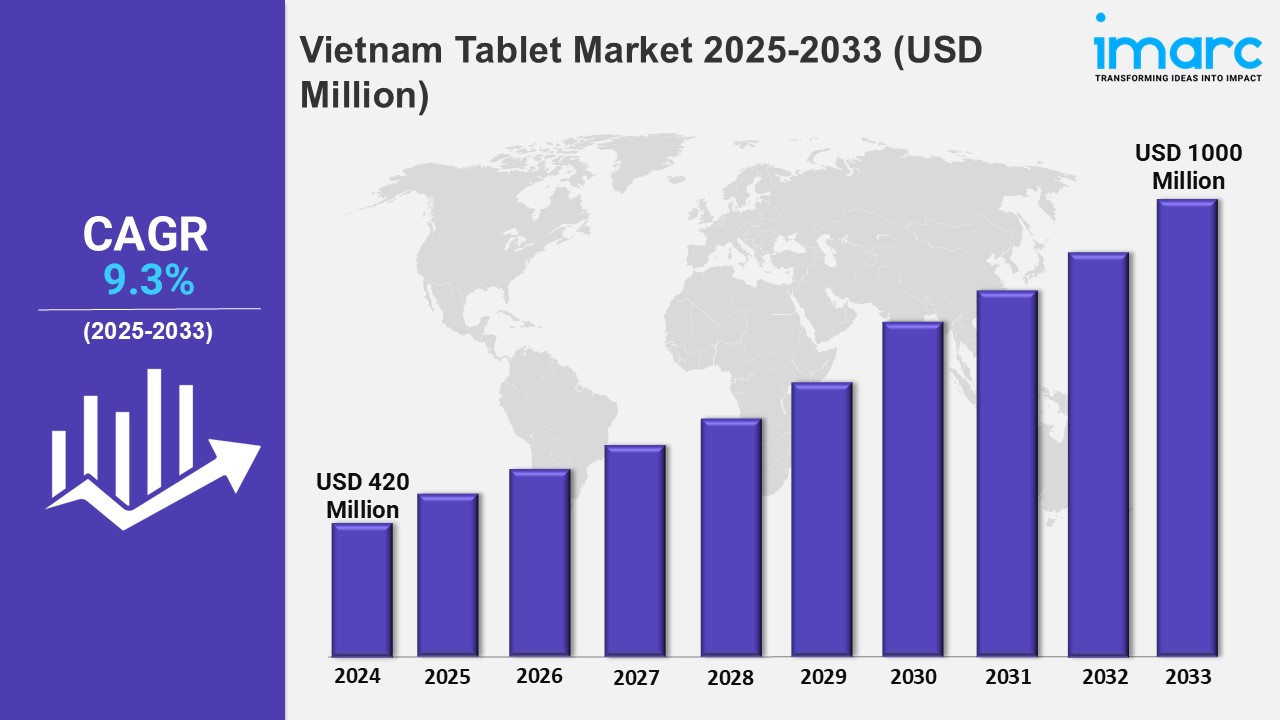

Global Market Insights

- Regional Hotspots

Asia-Pacific leads the charge, with China and India emerging as major players in both manufacturing and consumption.

Why Investing in a Cup Making Machine Is a Smart Move

- Scalability: Start small and scale production as demand increases.

- Customization: Print branding, sizes, and formats easily.

- Flexibility: Switch between materials and cup types with minimal downtime.

Tips for Choosing the Right Cup Making Machine

Key Factors to Consider

- Production speed

- Material compatibility

- Maintenance and support

- Cost vs. output ratio

- Energy consumption

Why Shanghai Zhanshi Should Be Your First Call

Shanghai Zhanshi Mechanical Equipment Co., Ltd. delivers dependability and creativity to every project because of its years of experience, cutting-edge equipment, and remarkable worldwide reach.

What once was a simple container is now a marvel of manufacturing ingenuity. Thanks to advanced Cup Making Machines, businesses can deliver quality, eco-conscious, and cost-effective paper cups at a scale that meets global demand. And with companies like Shanghai Zhanshi Mechanical Equipment Co., Ltd. leading the charge, the future of cup production is not only brighter—it’s smarter.

FAQs

1. What materials can a cup making machine from Shanghai Zhanshi use?

Their machines support PE-coated paper, PLA biodegradable materials, and other eco-friendly options.

2. How fast can a Zhanshi cup making machine produce?

Models like the ZS-1220 can produce between 90–130 cups per minute, depending on configuration and material.

3. Is it easy to change cup sizes on the machine?

Yes! With the right tooling, operators can quickly switch molds to produce different cup sizes and shapes.

4. Are these machines eco-friendly?

Of course, Shanghai Zhanshi creates devices that promote biodegradable materials and cut down on trash.

5. Does the business offer after-sales support or training?

Yes, they offer full support, including installation, training, maintenance, and parts replacement worldwide.