In the ever-evolving world of industrial manufacturing, the demand for high-quality materials that can withstand extreme conditions, provide reliability, and maintain precision is higher than ever. Among these materials, precision steel tubes stand out as a critical component in various industries. These tubes are designed to meet exact specifications, ensuring that your machinery operates at peak efficiency while maintaining its longevity.

At Shandong Baokun Metal Material Co. Ltd, we understand the importance of using the best materials for industrial applications. With years of experience in the steel industry, we provide premium precision steel tubes that ensure your operations remain smooth and trouble-free.

What Are Precision Steel Tubes?

Precision steel tubes are tubes made from high-quality steel that are processed to exacting specifications. The defining characteristic of these tubes is their ability to meet precise dimensional and surface finish requirements. These tubes are manufactured to tight tolerances, ensuring that their internal diameter, wall thickness, and overall structure are uniform and consistent.

The manufacturing process of precision steel tubes typically involves a combination of cold drawing and heat treatment. This process results in a product with a smooth surface, accurate dimensions, and high mechanical strength. These tubes are often used in applications where the tubes’ performance, durability, and precision are essential to the overall functionality of the system.

Applications of Precision Steel Tubes

Precision steel tubes are used in a wide range of industries, including:

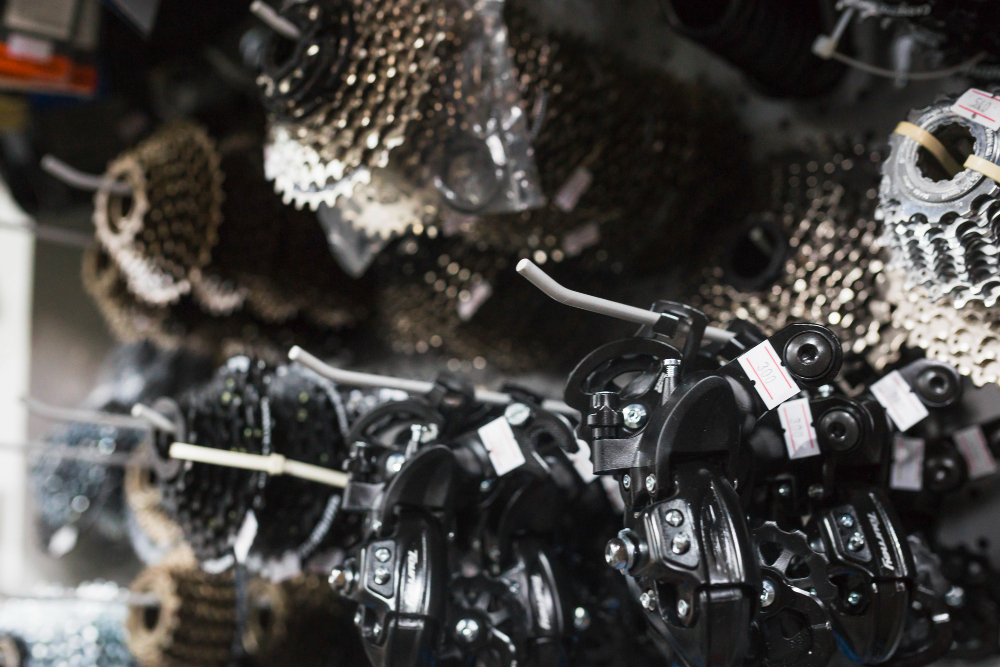

- Automotive Industry: For components like exhaust systems, fuel injection systems, and hydraulic systems.

- Construction: For structural steelwork and framework.

- Hydraulic Systems: As part of the tubing used in hydraulic cylinders and other high-pressure applications.

- Mechanical Engineering: In machinery where tight tolerances are required for the smooth operation of moving parts.

- Pneumatic Systems: For transporting compressed air or gases with precision.

Why Precision Steel Tubes Matter in Industrial Applications

Enhanced Performance and Efficiency

One of the key reasons precision steel tubes are so important is their ability to enhance performance and efficiency in machinery. The precise dimensions of the tube ensure that components fit together as intended, reducing friction, wear, and inefficiencies. For example, in hydraulic systems, precision steel tubes allow fluids to flow smoothly without unnecessary resistance, which maximizes the system’s efficiency.

In high-pressure environments, such as in the aerospace or automotive sectors, precision is vital. Even the slightest deviation in the tube’s dimensions can lead to leaks, performance issues, or even catastrophic failures. By using precision steel tubes, you reduce the risk of costly downtime or repairs, which is essential for maintaining your business operations.

Increased Durability and Longevity

Precision steel tubes are manufactured to withstand harsh conditions, making them highly durable and long-lasting. Their high resistance to wear and tear ensures that equipment operates optimally for longer periods. This durability is especially critical in sectors like construction, mining, and oil and gas, where machinery is subjected to extreme conditions such as high pressures, temperatures, and mechanical stress.

By investing in high-quality precision steel tubes, you are essentially investing in the longevity of your machinery and equipment. These tubes are engineered to resist corrosion, wear, and fatigue, which ensures that your systems run smoothly over extended periods, reducing the need for frequent replacements or repairs.

Reduced Maintenance Costs

Another significant benefit of using precision steel tubes is their contribution to lowering maintenance costs. Since these tubes are designed to provide superior performance and durability, the frequency of breakdowns and malfunctions is significantly reduced. This directly translates into fewer repair bills, less downtime, and a reduction in the overall maintenance costs of your machinery.

Precision tubes that fit properly and maintain their structural integrity reduce the wear on surrounding components. This extends the life of other machinery parts, ensuring that the entire system operates with greater efficiency and at a lower cost.

Factors to Consider When Choosing Precision Steel Tubes

Material Quality

The quality of the steel used in the manufacturing of precision tubes is critical. Higher-grade steel ensures that the tubes can withstand extreme temperatures, high pressures, and corrosive environments. When sourcing precision steel tubes, it’s important to inquire about the grade of steel used, as well as any treatment processes the material undergoes to ensure its longevity and performance.

At Shandong Baokun Metal Material Co. Ltd, we only use premium steel grades that meet the industry’s toughest standards, ensuring that every precision steel tube we supply is ready for high-demand applications.

Manufacturing Process and Tolerances

The manufacturing process of precision steel tubes is highly sophisticated, and it’s important to understand the specific methods used by the supplier. Cold drawing, heat treatment, and polishing are just a few of the techniques employed to create tubes that meet precise dimensional and surface finish specifications. A reputable supplier will be able to provide detailed information about their manufacturing process and the tolerances they are able to meet.

When choosing a precision steel tube supplier, it’s essential to verify that their manufacturing capabilities can meet the precise requirements of your application. Tubes that do not meet the specified tolerances may lead to malfunctioning components and decreased performance.

Certifications and Quality Assurance

Quality assurance is another important factor when choosing a precision steel tube supplier. Reputable suppliers will adhere to international quality standards, such as ISO certifications, to ensure that their products meet the highest levels of performance and reliability. Certifications also indicate that the supplier is committed to maintaining rigorous quality control processes throughout the production cycle.

Make sure to ask your supplier about the certifications they hold and whether they conduct thorough inspections and tests on their tubes to guarantee their quality.

The Role of Precision Steel Tubes in Specific Industries

Automotive Industry

In the automotive industry, precision steel tubes are used for a variety of critical components, including fuel lines, exhaust systems, and suspension parts. These tubes must be highly resistant to heat, pressure, and wear. Their precise dimensions ensure that components fit perfectly within complex systems, preventing leaks and malfunctions.

Oil and Gas Industry

The oil and gas industry relies heavily on precision steel tubes to transport fluids, gases, and oil at high pressures. These tubes must withstand extreme conditions, such as high pressures and corrosive substances, and maintain their integrity over long periods. Precision steel tubes provide the durability and strength needed to meet these challenges.

Aerospace and Aviation

In aerospace applications, where safety and performance are paramount, precision steel tubes are used in everything from hydraulic systems to aircraft fuselages. These tubes must meet incredibly tight tolerances and undergo rigorous testing to ensure their reliability in high-stress environments. Their ability to withstand extreme forces and temperatures makes them indispensable in this sector.

How to Choose a Reliable Precision Steel Tube Supplier

Reputation and Experience

A supplier with a strong reputation and extensive experience in providing precision steel tubes is likely to offer high-quality products. Look for a supplier with a proven track record of delivering tubes that meet industry standards and customer requirements. Shandong Baokun Metal Material Co. Ltd has built a strong reputation over the years by providing premium-quality steel products to clients worldwide.

Customer Service and Support

In addition to offering high-quality tubes, a reliable supplier should provide excellent customer service. They should be responsive to your inquiries, offer technical support, and assist you with selecting the right products for your specific needs. Customer service is an often overlooked factor, but it can make a significant difference in ensuring that you receive the right product and support when you need it most.

Precision steel tubes are a crucial element of many industrial applications, offering benefits such as enhanced performance, increased durability, and reduced maintenance costs. By selecting high-quality tubes from a reliable supplier like Shandong Baokun Metal Material Co. Ltd, you ensure the longevity and efficiency of your machinery, helping you achieve better productivity and minimize downtime. Whether you are in the automotive, aerospace, or construction industry, precision steel tubes are indispensable for meeting your operational goals and maintaining the highest standards of performance.

FAQs

- What makes precision steel tubes different from regular steel tubes?

Precision steel tubes are manufactured to very tight tolerances, ensuring precise dimensions and smooth surfaces. This makes them ideal for applications where accuracy and performance are critical.

- Why are precision steel tubes important for hydraulic systems?

Hydraulic systems rely on precision steel tubes to ensure that fluids flow smoothly and without leakage. The precise fit of the tubes helps reduce friction and wear, improving the system’s efficiency and durability.

- Can precision steel tubes be customized for specific applications?

Yes, precision steel tubes can be customized in terms of size, thickness, and surface finish to meet the unique requirements of your application.

- How do I know if a supplier provides high-quality precision steel tubes?

Look for a supplier with a strong reputation, industry certifications, and a track record of providing reliable products. It’s also important to ensure they perform thorough quality checks and offer excellent customer support.

- How can precision steel tubes help reduce maintenance costs?

By using high-quality precision steel tubes, you can reduce the risk of equipment failure, minimize wear and tear, and extend the lifespan of your machinery, which ultimately lowers maintenance costs.