The food packaging industry is undergoing a transformation, and at the center of it is smart vacuum sealing. With AI-driven automation redefining efficiency, precision, and quality control, businesses are finding new ways to extend shelf life, reduce waste, and enhance operational workflows. Let’s explore how AI and automation are shaping the future of vacuum sealing and what it means for manufacturers, retailers, and consumers.

AI-Powered Precision & Consistency

One of the biggest advantages of AI-driven vacuum sealing is its ability to optimize sealing parameters. Traditional vacuum sealers require manual adjustments based on the type of product being sealed, but smart sealers equipped with AI can automatically detect moisture levels, packaging material, and even air content to adjust settings in real time. This reduces human error and ensures a consistently perfect seal every time.

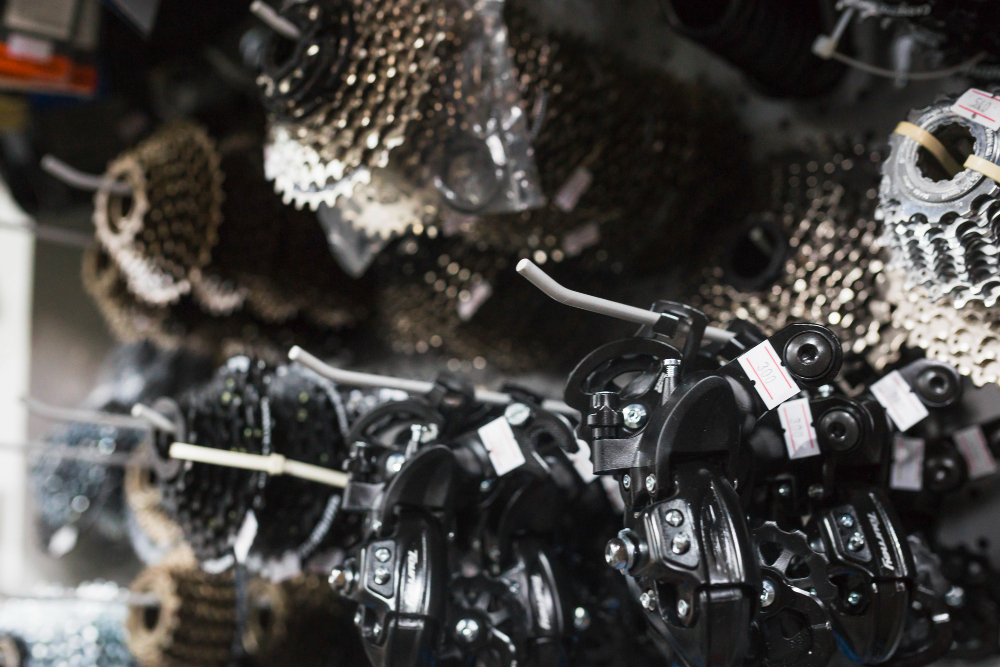

Automation in High-Volume Production

In commercial settings, speed and efficiency are critical. Automation has enabled vacuum sealers to handle large-scale operations with minimal human intervention. AI-powered conveyor systems can detect and sort products, initiate sealing cycles, and even perform quality checks. This not only speeds up production but also reduces labor costs and increases overall throughput.

Enhanced Quality Control with Smart Sensors

Smart vacuum sealers are now integrating advanced sensor technology to detect issues before they impact product quality. These sensors monitor vacuum pressure, temperature, and seal integrity in real time, flagging any inconsistencies immediately. By reducing the chances of defective packaging, businesses can maintain higher standards of quality and reduce product recalls.

Data-Driven Decision Making

AI-powered vacuum sealing systems are capable of collecting and analyzing data from every sealing operation. This data can help businesses identify trends, predict equipment maintenance needs, and optimize packaging processes. For example, predictive analytics can alert operators when a machine is likely to require servicing, reducing unexpected downtime and increasing overall efficiency.

Sustainability & Waste Reduction

With AI automation, vacuum sealing can be more sustainable than ever. By optimizing vacuum levels and sealing times, smart systems minimize material usage while maintaining airtight seals. Additionally, precise control over the packaging process reduces food waste, as AI-driven adjustments help prevent improper seals that can lead to spoilage.

The Future of Smart Vacuum Sealing

As AI and automation continue to advance, vacuum sealing will become even smarter. Integration with IoT devices will enable remote monitoring and control, while machine learning algorithms will refine sealing processes over time. The result? Greater efficiency, lower costs, and improved product preservation.

Businesses that embrace AI-powered vacuum sealing are positioning themselves for a future of optimized operations and increased profitability. The shift towards smart packaging solutions is not just an innovation—it’s a necessity in a competitive market.