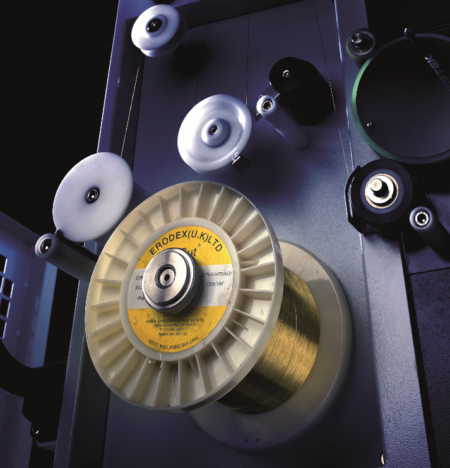

Since its founding in 1983. Erodex has become a renowned global leader in the supply and manufacturing of high-quality EDM (Electrical Discharge Machining) components. With decades of experience, the company offers a wide range of products tailored to meet the specific needs of the EDM industry, including electrodes. Filtration systems, wire guides & trolleys, nozzles, and various consumables. Whether you’re looking for standard components or specialized solutions, Erodex ensures that every product delivers the highest level of precision and reliability.

A Legacy of Precision and Innovation

Erodex’s journey began in 1983 under the name Kincast Ltd in England’s West Midlands. Initially focused on providing metal cutting tools for sectors such as aerospace and automotive engineering, Kincast quickly realized the need for more specialized components. This led to a shift in the company’s focus toward Electrical Discharge Machining (EDM). As Kincast transitioned into Erodex, the company became one of the first to dedicate itself entirely to the production of top-grade EDM electrodes, revolutionizing the industry with innovations in precision.

With the rise of non-standard designs, Erodex transformed the way electrodes were produced, allowing for fast, accurate, and repeatable results. Their specialized electrodes helped streamline the process of precision machining, ensuring manufacturers could meet stringent quality requirements for a variety of industries.

Advancing Manufacturing Capabilities

In 2008, Erodex took a significant step forward by moving into a state-of-the-art manufacturing facility. This new location not only provided the company with expanded machine shop capabilities but also enabled them to meet growing demand by producing custom components in a wide range of sizes and specifications. The facility allowed Erodex to accelerate production and improve efficiency, offering faster turnaround times for their customers.

As the demand for Wire EDM technology grew, Erodex recognized the opportunity to enhance its offerings in this niche area. Wire EDM is an advanced process where a wire is used to electrically cut through conductive materials with extreme accuracy. Erodex became a trusted supplier of specialized components that supported this innovative process, ensuring the best results for manufacturers in need of precision parts.

Embracing Modern Technologies

Erodex’s commitment to remaining at the forefront of the EDM industry has led the company to embrace cutting-edge technologies. In recent years, Erodex has leveraged 3D printing technologies to create custom parts and complete assemblies. This modern approach enables the company to provide bespoke solutions that meet the specific needs of individual projects. All while improving production speeds and reducing lead times compared to traditional manufacturing methods.

With 3D printing, Erodex can produce highly specialized components that are designed for optimal performance in Wire EDM applications. This advancement, combined with their deep expertise in the EDM field, allows Erodex to remain ahead of industry trends and provide innovative solutions that enhance efficiency for their clients.

Quality and Reliability at the Core

At the heart of Erodex’s success lies its unwavering commitment to quality. Every product manufactured by Erodex undergoes rigorous quality control processes, ensuring it meets the highest standards of precision. The company’s dedication to providing reliable, high-performance components has made it the preferred choice for industries where precision is critical. Such as aerospace. automotive, medical, and mold making.

Erodex’s team of experts works closely with customers to provide tailored solutions that align with the specific needs of their Wire EDM operations. Whether you require standard EDM components or highly customized solutions. Erodex’s reputation for quality ensures that you’ll receive the best possible products to support your operations.

The Future of Erodex

Looking ahead, Erodex is committed to maintaining its position as a leader in the EDM industry. The company continues to innovate, expanding its technological capabilities and refining its products to meet the evolving demands of the market. With a focus on precision, efficiency, and customer satisfaction, Erodex remains dedicated to providing the highest-quality Wire EDM components, ensuring that manufacturers can meet the increasing demands for complex, high-precision parts.

Conclusion

For over four decades. Erodex has been synonymous with excellence in EDM components, particularly in the area of Wire EDM. Their ongoing commitment to quality, innovation, and precision has made them a trusted partner for industries across the globe. Whether you need standard electrodes. Specialized Wire EDM components, or custom solutions, Erodex offers the expertise and cutting-edge technology to support your manufacturing needs, today and in the future.