Conversely, an adverse material yield variance suggests lower production achieved during a period for the given level of input resulting in higher material cost. In general, it can be assumed in exam questions that the production manager is responsible for the mix of input materials used. It can be tempting for production managers to change the product mix in order to make savings; these savings may lead to greater bonuses for them at the end of the day. However, if the quality of the product is adversely affected, this is damaging to the reputation of the business and hence its long‑term survival prospects. While substituting lower quality or cheaper input materials may in some cases lead to yield volumes that are the same as those achieved with higher quality materials, the yield may not be of the same quality.

- The most important similarity, for my purposes anyway, is that this pattern involves developing an expectation and comparing actual results against that expectation in a controlled and careful way.

- The standard price for this direct material is only $80 per ounce.

- Discuss the issues that management should consider when setting standard material costs.

- Beta Company processes three materials, namely, material A, material B, and material C, to produce its only product known as product K.

- To avoid confusion I do not use the term flexible budget for this variance.

Get in Touch With a Financial Advisor

Overapplied or underapplied overhead is basically the same as a favorable or unfavorable variance, it just isn’t broken up yet into the individual variable and fixed overhead variances. If you have a low allocated fixed cost figure, it likely means you underutilized the capacity you bought with a fixed cost, and that wasted capacity is unfavorable. But you produced a very low volume with that factory, leading to very low consumption of the cost driver, leading to a very low allocated fixed overhead cost figure.

2.4 Quick Note on Multi-product Firms’ Sales Volume Variance

Potential actions could include checking machinery, retraining employees, or analyzing the quality of the raw materials. The yield variance is one of the more common manufacturing metrics. The articles and research support materials available on this site are educational and are not intended to be investment or tax advice. All such information is provided solely for convenience purposes only and all users thereof should be guided accordingly. Calculating DLYV is important to assess the productivity of labor and identify areas where operational efficiency can be improved. Read on as we take a deeper look at yield variance, as well as the formula used, what it indicates, and answer some of your frequently asked questions.

The control of production processes in manufacturing environments

For Kappa Co, if the only variance calculated was the favourable usage variance, then it would be assumed that the production manager had demonstrated a good performance and obtained more efficient production. When the mix and yield variances are considered, it is clear that the positive usage variance is caused by a change in the mix of inputs. It will need to be considered what impact this change of mix has had on the quality of the finished product and ultimately on sales.

11 Financial’s website is limited to the dissemination of general information pertaining to its advisory services, together with access to additional investment-related information, publications, and links. Finance Strategists has an advertising relationship how to calculate straight line depreciation with some of the companies included on this website. We may earn a commission when you click on a link or make a purchase through the links on our site. All of our content is based on objective analysis, and the opinions are our own.

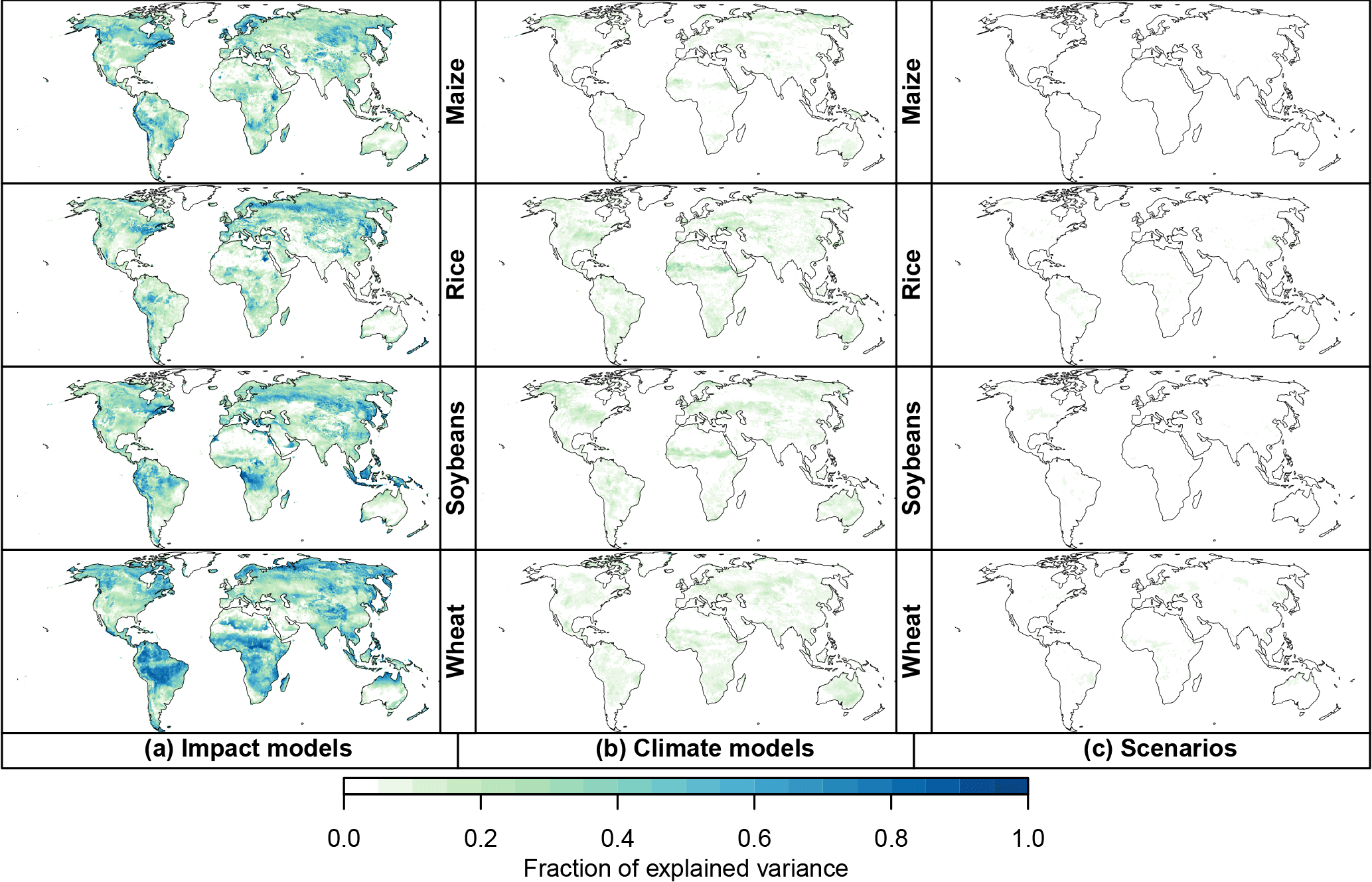

To complete the table, the actual quantity in the standard mix needs to be calculated using the standard proportions given in the question. In cells B4 to D4, calculate the amount of materials Alpha, Beta and Gamma that would have been used if the total quantity of 5,620kg had been input using the standard mix. Yield variance is one of the most used industrial metrics and is used to gauge how successfully a production process produces final goods.

By analyzing yield variances, investors can gauge the reliability of their income streams and the stability of their investment portfolios. For a full appreciation of the impact of the mix change, the sales variances would also have to be considered, although it is likely to take time for sales volumes to be affected. The mix variance is calculated as the difference between the actual total quantity used in the standard mix and the actual quantities used in the actual mix, valued at standard costs.

Again, this should be considered where information concerning this has been provided in the question. This favorability works like prior favorability for two reasons. First, as with the prior costs, if the left-hand number is higher than the right-hand number, then it is an unfavorable variance (see the diagram above). The diagram above correctly shows the static budget’s fixed overhead cost as being more leftward (or less hypothetical) than the allocated fixed overhead cost. Allocated fixed overhead cost is more contrived than static budget fixed overhead cost because allocated fixed overhead cost is based on the consumption of the cost driver. And that cost driver (very likely) moves up and down as volume moves up and down.

The material yield variance is also known as the material usage variance and the direct material yield variance. The difference between the actual quantity of material used for a given amount of product and the standard quantity of the material required for that amount of product, priced at the standard cost per unit of material. Material yield variance is used in conjunction with material mix variance in order to provide additional analysis of the material usage variance. Always make sure you mention such interdependencies when discussing variances in exam questions. If we add together the material mix and yield variances, we get a favourable usage variance of $580 ($913 – $333). The yield variance can give unexpected results if the standard (expected amount) is set at an unattainable level.

The difference is sitting in the warehouse, waiting to be put into production. When I introduced job-order costing in Chapter 4, I simultaneously introduced “normal costing” (from the illustration linked above) even without naming it as such. Here’s the basic shape of variances (I’ll explain more on each piece of this diagram later).